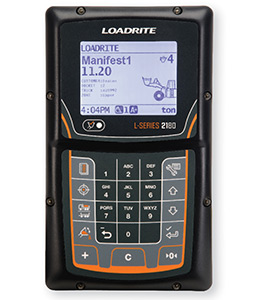

LOADRITE L2180 Reach Stacker Scales

Ensure compliance to SOLAS regulations, track and improve container handling with accurate weight information. The LOADRITE® L2180 weighing system verify the weights of every container moved, so you can provide accurate information for logistics compliance and reporting. The weight information can also be used to analyze your operation for efficiency improvement and maintenance cost reduction.

The L2180 is robust, easy to use and mounts into your reach stacker cab. With accuracy typically within +/- 1%, the system provides essential information to improve your operations.

- Increase process efficiency

- Increase traceability

- Improve work safety

Superior non-disruptive weighing technology

LOADRITE reach stacker systems provide repeatable accuracy on reach stacker machines, removing the need to interrupt workflow. The L2180 will even compensate for variances caused by inexperienced operators or weighing on rough ground to achieve +/-1% margin of error.

Overload warning

Promote safe loading in your operations by equipping your reach stacker operators with an overload warning included with the in-cab indicator system.

Multiple data field capture and reporting

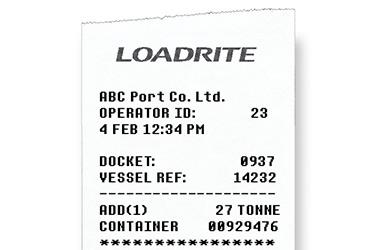

The LOADRITE L2180 allows container weights to be logged with other custom data including container ID, driver ID, date/time etc and then reported using either InsightHQ (web based) or MMS (for PC) reporting platforms.

Real time data logging

Not only will your reach stacker scale align to your existing workflow, but is capable of integrating with a selection of terminal enterprise system. Ask your dealer to explain options available.

How It Works

- Pressure transducers connect to the reach stacker hydraulic system. They sense the hydraulic pressure in the lift cylinders as the load container is lifted.

- Rotary trigger offers precision sensing throughout the lift cycle to ensure reliable and repeatable dynamic weighing.

- Rugged design and programmed with proprietary weighing software, the LOADRITE indicator provides an intuitive interface to the weighing system.

- Slope compensation kit allows the L2180 to weigh on angled or uneven terrain and still deliver superior accuracy (optional, but recommended).

- In cab printer allows you to document container weight data with the ruggedized printer. The printer can also provide daily and weekly productivity and performance reports (optional).

- Data communication solutions including data module, WiFi, radio, or 3G modem with GPS. The 3G modem with GPS option connects the scale to InsightHQ reporting portal so that you can check your site productivity and performance at anytime and anywhere. (optional).

- A proximity sensor is fitted to ensure weighing takes place only when the telescopic boom is fully retracted (recommended)